SPH1299™ V2

Robust, precise and easy to use

Pressure up to 1.300 bar

True automatic self-priming

Automatic solvent compressibility compensation

Easy and economic user maintenance

Reliable performance

SPH1299™ V2 is based on the reliable, proven concept of linear drive technology for two pairs of serially coupled pump heads. Each of the four pump heads is individually driven and controlled. This generates maximum freedom for flow control and pulse reduction, resulting in a stable and accurate flow, independent of solvent compressibility, pressure and flow rate. In addition to the standard Sapphire seat, one can also opt for a Zirconia seat, to reduce polymer residue build-up.

Key features

True automatic self-priming

A novel automatic priming concept fully automates the priming procedure. A built-in prime pump aspirates solvent through the pump heads when starting with empty solvent inlet lines.

Reliable and robust performance

Using linear driven technology for two pairs of serially coupled pump heads, resulting in a stable and accurate flow. You will experience ultra-precise solvent gradients.

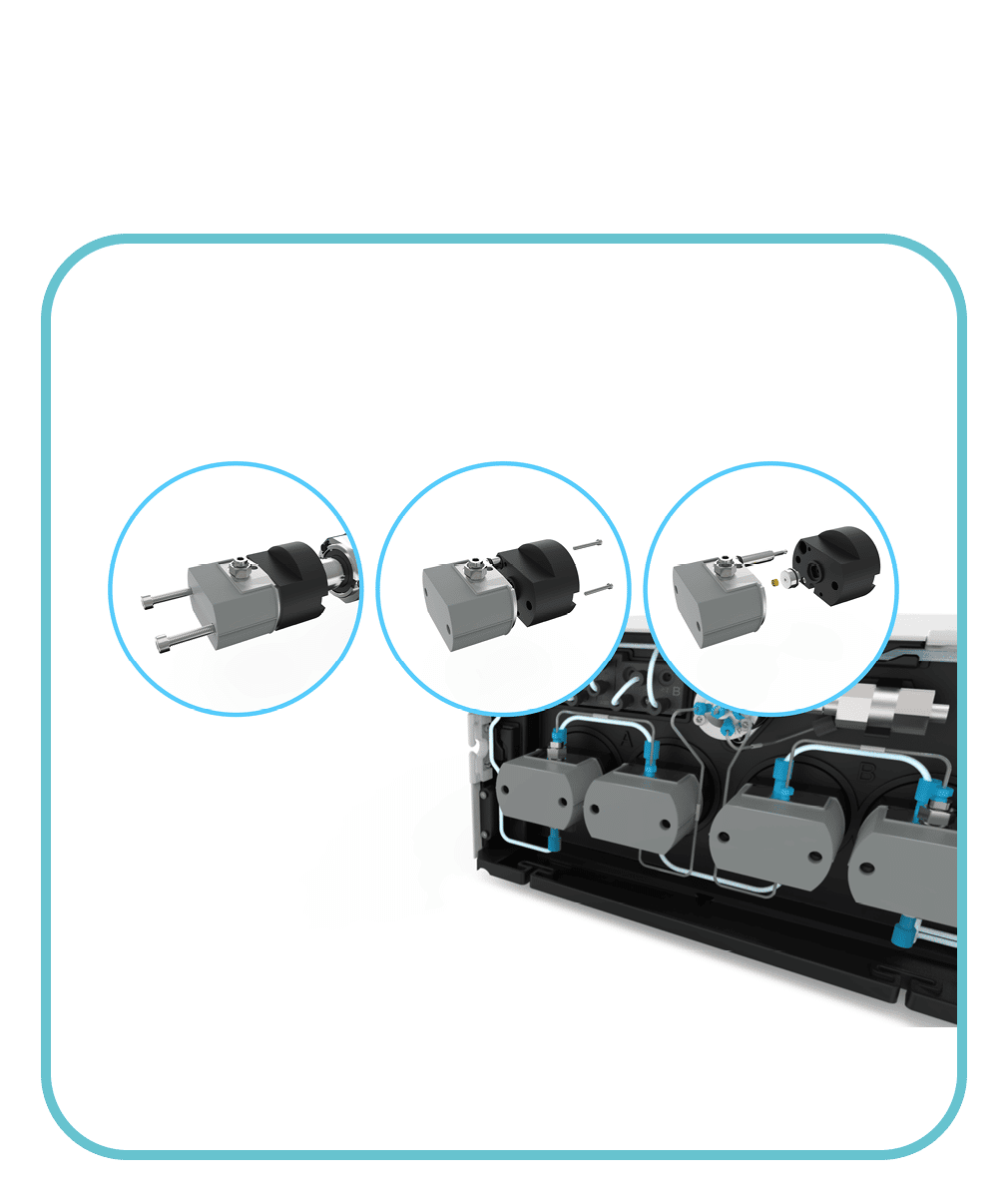

Easy and economic user maintenance

The pump head has been designed for easy disassembly and seal exchange. No need to remove covers or expensive exchanges of entire pump assemblies. Simply disconnect, remove and replace.

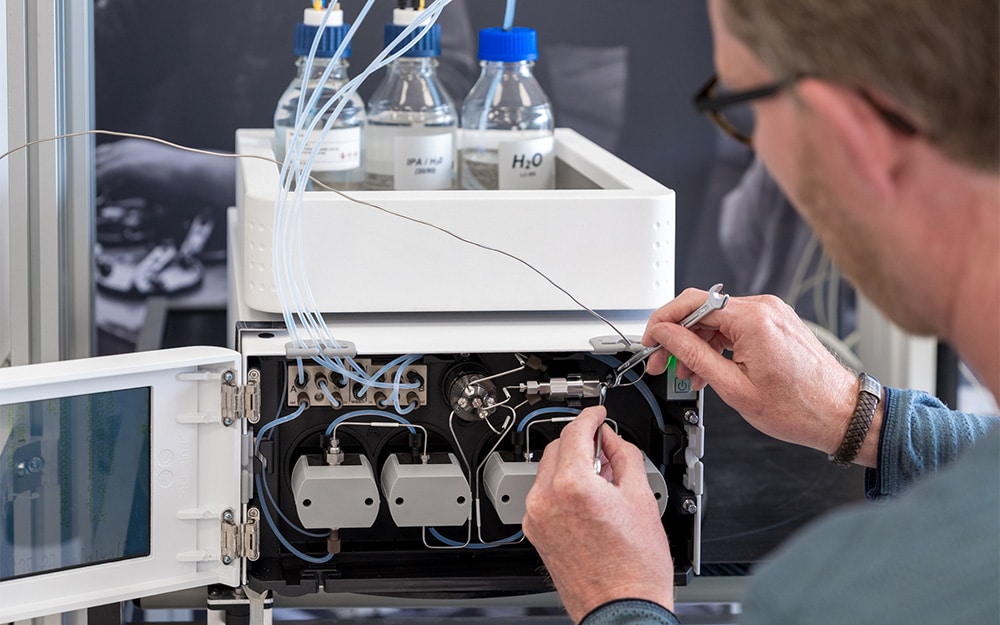

Easy maintenance

Purging, disconnecting and even piston replacement are no longer a threshold for you. Using an electrically actuated purge valve, SPH1299™ V2 can truly prime and purge all by itself. No need to help your pump with a syringe for awkward manual solvent aspiration. Up-time of the pump is increased by the active piston backwash. But eventually a seal will need replacement. The pump head has been designed to facilitate easy disassembly and seal exchange in just minutes. Simply disconnect, remove and replace. Besides, the force distribution of the seal is such that it is not possible to break the check valve. The complete pump head is made of high quality 316 stainless steel, with a high-tech coating.

Find out all about our products, commitment, lead times and support.

Discover our passion for the continuous improvement of your liquid sample workflows.